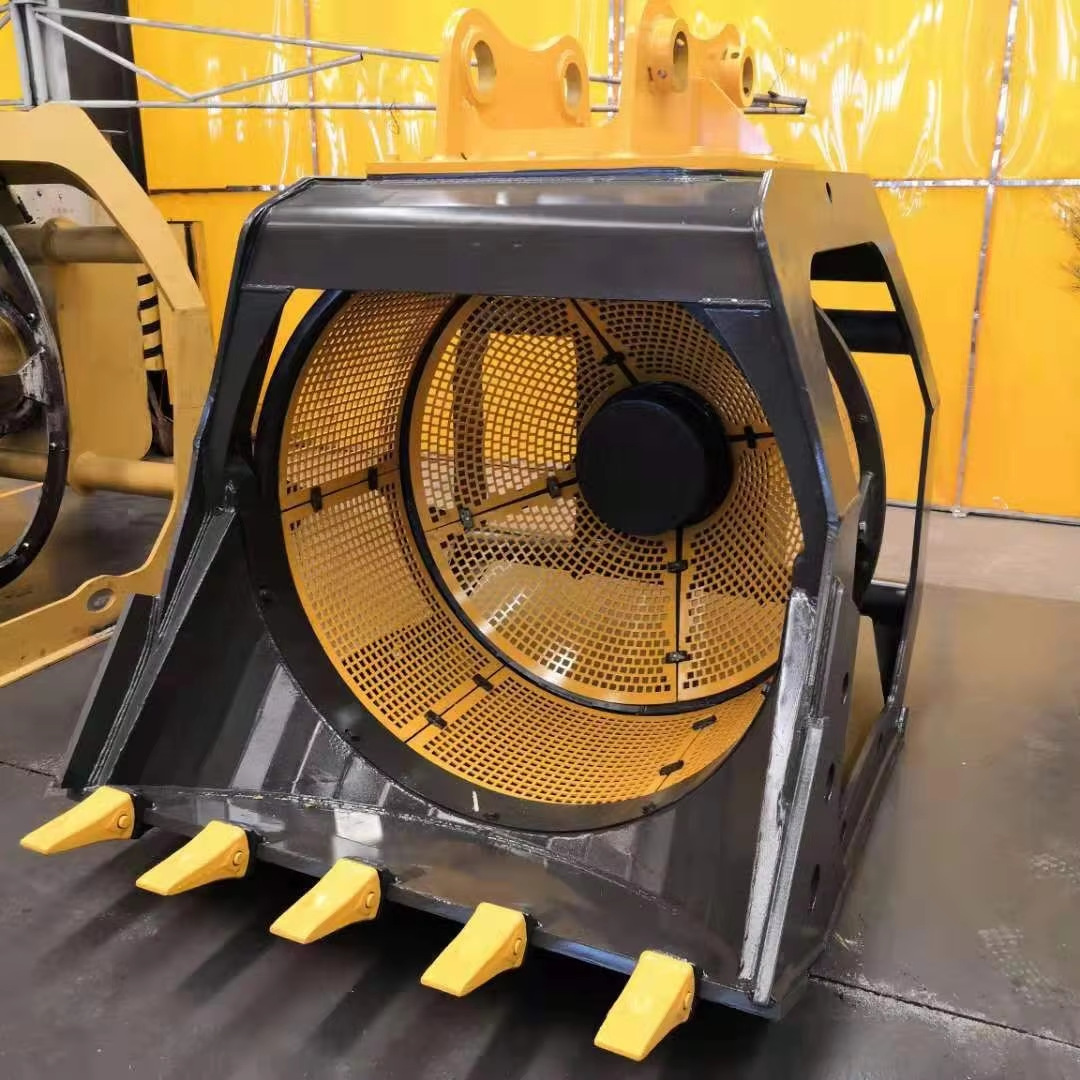

As the core component of the excavator directly contacting the working object, the Bucket of Backhoe is an indispensable "execution terminal" in the construction chain.Its performance and quality are directly related to the efficiency, cost and safety of the project, and it bears an irreplaceable key significance in various construction scenarios.

From the perspective of construction efficiency, the excavator bucket is the "efficiency engine" that determines the progress of the project.Through scientific bucket design and suitable specifications and models, high-quality buckets can accurately match different operation requirements such as earthwork excavation, material transfer and site leveling, reduce ineffective operation cycles, and achieve maximum efficiency transformation for each excavation and loading action.In large-scale infrastructure, mining and other projects with tight construction period, the bucket with stable performance can directly shorten the operation cycle and provide core support for the timely delivery of the project.