Understanding Excavator Auger Types and Their Applications

Earth, Rock, and Ice Augers: Key Differences and Use Cases

Different types of excavator augers work best with certain materials. The earth augers handle soft to medium density soils pretty well, which makes them great choices for things like landscaping jobs, setting up farm fences, or putting in those utility poles we see everywhere. Rock augers come with these tough carbide teeth that let them cut through really hard stuff like limestone and concrete. A recent survey from 2023 actually found they can save about 40% of drilling time when working on rocky sites compared to regular models. Ice augers aren't used as often but become absolutely necessary in colder regions. These special tools use steel that stands up to extreme temperatures, allowing workers to drill into permafrost or frozen ground while doing infrastructure work in winter months.

Common Auger Bit Designs and Matching Them to Ground Material

The efficiency of an auger depends heavily on bit design:

- Helical flights work best in clay, continuously removing debris and minimizing clogging

- Paddle-style bits stabilize loose sand with wide, shallow scoops that reduce collapse risk

- Conical carbide tips maintain alignment when encountering hidden obstructions in mixed soils

Selecting the right design ensures clean hole formation and reduces wear on both the bit and excavator.

When to Use Tungsten-Tipped Augers for Extreme Conditions

When working with really tough stuff like shale or reinforced concrete, most professionals reach for tungsten tipped augers instead of regular steel ones. The difference is pretty dramatic actually these specialized bits tend to last anywhere from three to five times longer when pushed through harsh conditions. That makes them worth the extra investment especially for big operations where downtime costs money. Recent improvements in metal science have made these augers much better at handling two main problems faced in field work: sudden impacts from hard rock layers and constant rubbing against walls while drilling deep holes. What this means practically is equipment stays reliable longer and gets more done between replacements.

Matching Auger Type to Soil Composition and Ground Conditions

How Clay, Sand, Rock, and Mixed Soils Impact Auger Performance

The makeup of soil has a big impact on how well drilling works and how long equipment lasts. With clay, the problem comes from its sticky consistency which creates extra friction and tends to gum things up. The solution? Go for smoother flighting with more space between the blades. When working in sandier ground, tighter helix designs actually help keep things stable as material gets pulled out, cutting down on those frustrating cave-ins somewhere around 30% better than regular bits according to some field tests last year. For rockier areas, nothing beats tools with hardened steel or carbide teeth that can chip away at tough layers. And let's not forget about mixed soils where no single approach works best. That's when hybrid augers come into play with their adjustable cutting angles that switch gears depending on what kind of dirt they're digging through next.

Selecting the Optimal Auger for Challenging Terrain

When working on hillsides or rough ground, the strain on hydraulic systems gets pretty intense. For those sticky mud situations, shallow flight augers can actually stop the whole thing from getting stuck. And when dealing with frozen earth, those tapered pilot bits really work wonders breaking through without needing too much force pushing down. Some research back in 2023 showed interesting results too. They paired together those slower spinning but stronger torque augers with bigger machines pumping out around 18 gallons per minute of hydraulic power. The outcome? Machines stalled way less often in icy soil conditions something like half the time less than before according to their findings.

Case Study: Improving Efficiency in Rocky Soil with Tungsten-Tipped Rock Augers

The recent highway expansion near Denver made quite an impact when crews switched from regular carbide bits to those with tungsten tips for rock drilling. What they found was remarkable actually – drill bit replacements dropped by around 70%, which saved them a lot of downtime. When boring through sedimentary rock layers, operators noticed their penetration rate jumped to about 1.2 times faster than before. This translated into getting all 138 foundation holes drilled three full days earlier than originally planned. And there's another bonus too: fuel usage went down roughly 15% per hole. For contractors working on tight budgets and schedules, these results show why investing in specialized drilling equipment can pay off big time in terms of both wallet savings and project timelines.

Determining the Correct Auger Size: Hole Diameter and Drilling Depth

Key factors in selecting auger diameter and depth for project accuracy

Picking the correct auger size means looking at what kind of soil we're dealing with, what the structure needs to hold up, and those technical specs engineers always mention. When installing fence posts, something between 6 and 12 inches usually works fine. But when talking about foundation piers for bigger projects, we need much wider holes, around 24 to 36 inches across, since these have to carry substantial weight. How deep we go matters too. Light duty poles might only need a hole about four feet down, while geothermal installations can require digging well over twenty feet into the earth. According to research published last year by geotechnical experts, almost 37 out of every 100 foundation problems in areas with mixed soil types come from getting the hole dimensions wrong. That's why matching the auger specs exactly to both the ground makeup and the construction drawings isn't just good practice—it's absolutely critical.

Balancing reach and torque in deep-hole drilling applications

The deeper we drill, the more hydraulic torque becomes necessary. For every extra 10 feet downhole, operators typically need about 18 to 22 percent extra power just to keep things spinning efficiently. Big augers over 30 inches across struggle in tough soil conditions beyond roughly 15 feet before they start bending or deflecting. On the flip side, smaller 12 inch diameter bits work surprisingly well in solid clay formations reaching depths of around 40 feet if connected to good quality high flow hydraulics. When considering machine capacity, most excavators weighing less than 20 tons simply cannot handle going much past 25 feet with regular rock augers. But those heavy duty machines above 30 tons? They've been known to punch through to about 50 feet underground using specially designed tapered earth augers that stay straighter during operation.

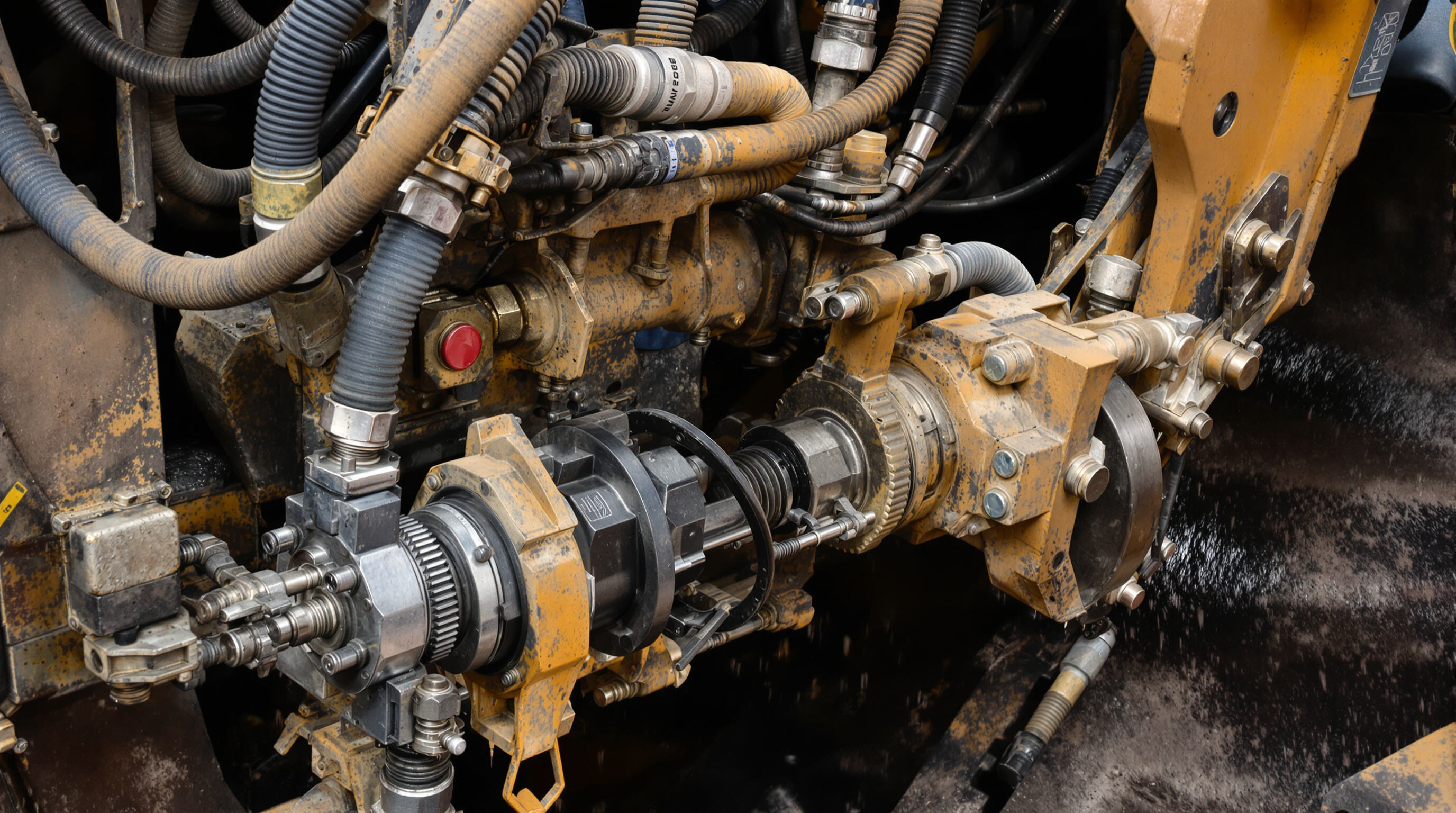

Ensuring Hydraulic Compatibility Between Excavator and Auger Attachment

Hydraulic compatibility is essential for efficient and safe auger operation. Properly matching flow rate, pressure, and coupler type ensures optimal power transfer and minimizes equipment damage.

Matching Auger Requirements With Excavator Flow Rate, Pressure, and Coupler Type

Excavators typically produce anywhere from 15 to 35 gallons per minute when it comes to hydraulic flow. Augers need between 8 and 28 GPM, and this depends largely on their size and what kind of material they're working with. When someone tries to attach a 20 GPM auger to a machine that only delivers 15 GPM, things don't work as well. Efficiency drops by about a quarter, and parts tend to wear out faster because the system is constantly under strain. Pressure specs also differ quite a bit. Regular augers run at around 3,500 to 5,000 pounds per square inch. But those fancy tungsten tipped versions sometimes demand systems that can handle up to 6,000 PSI. Getting the right quick couplers matters a lot here. Leaks are actually responsible for roughly 42% of all problems with attachments on earthmoving gear, so compatibility really pays off in the long run.

Avoiding Common Hydraulic Mismatches in Auger Operations

Three common errors compromise performance:

- Oversized augers exceeding the excavator’s hydraulic or lift capacity, leading to system overload

- Undersized hoses restricting flow and reducing torque by 15–30%

- Improper quick-coupler seals causing pressure drops and contamination

Operators should consult auger manufacturers’ specifications and match them to their excavator’s hydraulic output. For fleets with multiple machines, ISO 16028-compliant couplers streamline attachment swaps while maintaining pressure integrity. Conducting hydraulic fluid tests every 500 hours helps prevent viscosity-related issues, especially in extreme temperatures.

By ensuring hydraulic harmony, contractors can reduce downtime by up to 60% and extend the service life of both augers and host machines.

Aligning Auger Selection with Project Requirements and Operational Efficiency

From fencing to foundations: Choosing the right excavator auger for specific jobs

Choosing the correct auger can make all the difference when it comes to getting the job done efficiently. When setting fences in softer ground conditions, most folks stick with standard earth augers featuring those spiral shaped flights for quick and neat drilling into 6 to 12 inch diameter holes. For foundation jobs where the soil is really packed tight, especially in clay, rock augers equipped with carbide teeth and extra strong flighting tend to hold up better for larger holes over 24 inches wide. Tree planters working with big specimens typically reach for those ice auger type attachments with sharp tapered bits that slice right through dense root systems without bogging down the machine. According to some research published last year, contractors who matched their augers specifically to the task at hand saw around a 19 percent reduction in drilling time versus just grabbing whatever generic attachment was handy.

Maximizing uptime and cost-efficiency with the right attachment choice

Getting the most out of drilling operations really comes down to matching those auger specs with what the job actually needs and what the equipment can handle. When operators stick oversized augers into hard rock formations, fuel costs jump around 22% according to Equipment Watch's latest report. On the flip side, going too small in soft soils means making about 34% more passes just to hit that target depth. Most field technicians will tell anyone who'll listen that keeping hydraulic systems within their sweet spot matters a lot. Flow rates between 8 and 25 gallons per minute work best alongside pressures ranging from 2,200 to 3,500 pounds per square inch. For RPM settings, aim for somewhere between 80 and 120 when working through typical soils, but crank it up past 150 if dealing with frozen ground conditions using those tungsten tipped bits. Don't forget regular checks on those shanks either. Replace worn cutting teeth approximately every 50 to 70 operating hours to keep things running smoothly and sidestep those expensive breakdowns nobody wants during critical projects.

FAQ

What is the difference between earth augers and rock augers?

Earth augers are suitable for soft to medium density soils, commonly used in landscaping and setting fences. Rock augers have tough carbide teeth ideal for cutting through hard materials like limestone and concrete, improving drilling efficiency by 40%.

Why would tungsten-tipped augers be preferred over regular steel augers?

Tungsten-tipped augers are favored for drilling through tough materials such as shale and reinforced concrete due to their durability, lasting three to five times longer than steel augers and helping reduce downtime.

How do soil types impact auger performance?

Sticky clay requires smoother flight augers, sandy soils benefit from tighter helix designs, rocky terrains need hardened steel or carbide teeth, and mixed soils often require hybrid augers with adjustable cutting angles.

What factors determine the correct auger size?

Factors include soil type, structural requirements, and technical specifications. Auger size is crucial for project accuracy and should be matched to soil composition to prevent issues like foundation problems.

How can hydraulic compatibility affect auger operations?

Matching auger requirements with excavator hydraulic output ensures efficiency and minimizes wear. Common hydraulic mismatches include incorrect flow rate, pressure settings, and coupler type.

Table of Contents

- Understanding Excavator Auger Types and Their Applications

- Matching Auger Type to Soil Composition and Ground Conditions

- Determining the Correct Auger Size: Hole Diameter and Drilling Depth

- Ensuring Hydraulic Compatibility Between Excavator and Auger Attachment

- Aligning Auger Selection with Project Requirements and Operational Efficiency

- FAQ