Superior Efficiency and Productivity in Hard Rock Saws Applications

High-Speed Cutting Performance in Dense Rock Environments

Rock saws cut up to 3x faster than pneumatic hammers in granite and basalt, thanks to diamond-impregnated blades operating at 1,200−1,800 RPM. Continuous hydraulic power eliminates the stop-start cycles of manual methods, maintaining momentum even in rock formations exceeding 250 MPa compressive strength.

Daily Output Gains: Cubic Meters Processed With Rock Saws vs. Traditional Methods

Field crews have noticed roughly an 85 percent boost in what they can get done each day when switching from traditional drilling and blasting to modern rock saw technology. Take an excavator mounted unit for instance it typically handles between 18 to 22 cubic meters of tough rock during an 8 hour workday. That's way ahead of what handheld breakers accomplish, which struggle to crack through just 10 or 12 cubic meters in the same timeframe. The main reason behind this improvement? Less time spent swapping tools around and better compatibility with existing equipment on site. Most operators find their workflow becomes much smoother once everything works together without constant interruptions for maintenance or tool changes.

Comparison of Mechanical Rock Saws and Blasting: Speed, Consistency, and Operational Flow

| Factor | Rock Saws | Blasting |

|---|---|---|

| Setup Time | 15−30 minutes | 4−8 hours (drilling + charge placement) |

| Cut Precision | ±2 mm tolerance | Unpredictable fracture zones |

| Post-cut Work | None (ready-to-use surfaces) | Debris removal + secondary shaping |

Mechanical cutting avoids the 12−48-hour safety clearance delays associated with blasting, allowing uninterrupted operations—even in urban environments.

Case Analysis: Blasting vs. Rock Saws in Safety, Environmental Impact, and Project Timelines

According to the 2023 Quarry Operations Report which looked at 47 different locations across the country, rock saw technology actually cut down on workplace injuries by about two thirds when compared to traditional blasting methods. The vibrations from these saws stay pretty low too, measuring around 8 mm/s. That's way below what we usually see with explosives, which typically range between 25 to 40 mm/s. This lower vibration level means there's much less risk to surrounding buildings and structures. Another interesting finding was that projects utilizing rock saws produced 92 percent fewer particles in the air and managed to wrap things up anywhere from 17 to 23 days earlier than expected. And if that wasn't enough, the report also mentioned something else worth noting: secondary processing expenses went down by roughly $18 to $27 per ton during granite extraction because the cuts were so much cleaner.

Unmatched Precision and Clean Cuts for High-Value Applications

Achieving Dimensional Accuracy in Hard Rock Like Granite and Marble

When working with tough stones like granite, rock saws typically stay within a tolerance range of plus or minus 1.5 mm, which helps keep dimensions pretty much spot on. The newer automated systems with diamond blades can get even better results, hitting around 0.01 inch accuracy on those big slabs that stretch over three meters long. This kind of precision really cuts down on wasted material. Studies show these machines reduce material loss somewhere between 18% and 22% compared to old fashioned manual scoring methods. That matters a lot when we're talking about premium quality stone that costs anywhere from $450 up to $800 for just one cubic meter. Every little bit saved adds up fast in this business.

Diamond-Tipped Blades: Enabling Clean, Smooth Cuts With Minimal Waste

Segmented diamond blades rotating at 1,200−1,500 RPM produce smooth, near-finished surfaces with 90−95% quality, eliminating the need for extensive finishing. These blades generate 40% less fine particulate (≤2.5µm) than abrasive alternatives and last 30% longer, reducing both environmental impact and maintenance frequency.

Reduced Need for Secondary Processing and Finishing Work

Projects using rock saws require 2.1 fewer hours of polishing per 10㎠ of cut surface compared to jackhammer-based methods. Smooth, chip-free edges eliminate repair work in 87% of installations, translating directly into a 12−15% reduction in labor costs for stone fabricators.

Case Study: Dimension Stone Quarry in Scandinavia Using Rock Saws for Exact Block Sizing

A Scandinavian quarry producing architectural-grade gneiss achieved 98% material utilization after adopting track-mounted rock saws. The system cuts 120-ton blocks to within ±5 mm in just 45 minutes−down from an 8-hour drilling and blasting process. Since 2021, this transition has reduced water consumption by 65% and shortened project timelines by 22% across 18 commercial developments.

Mobility, Versatility, and Integration with Existing Equipment

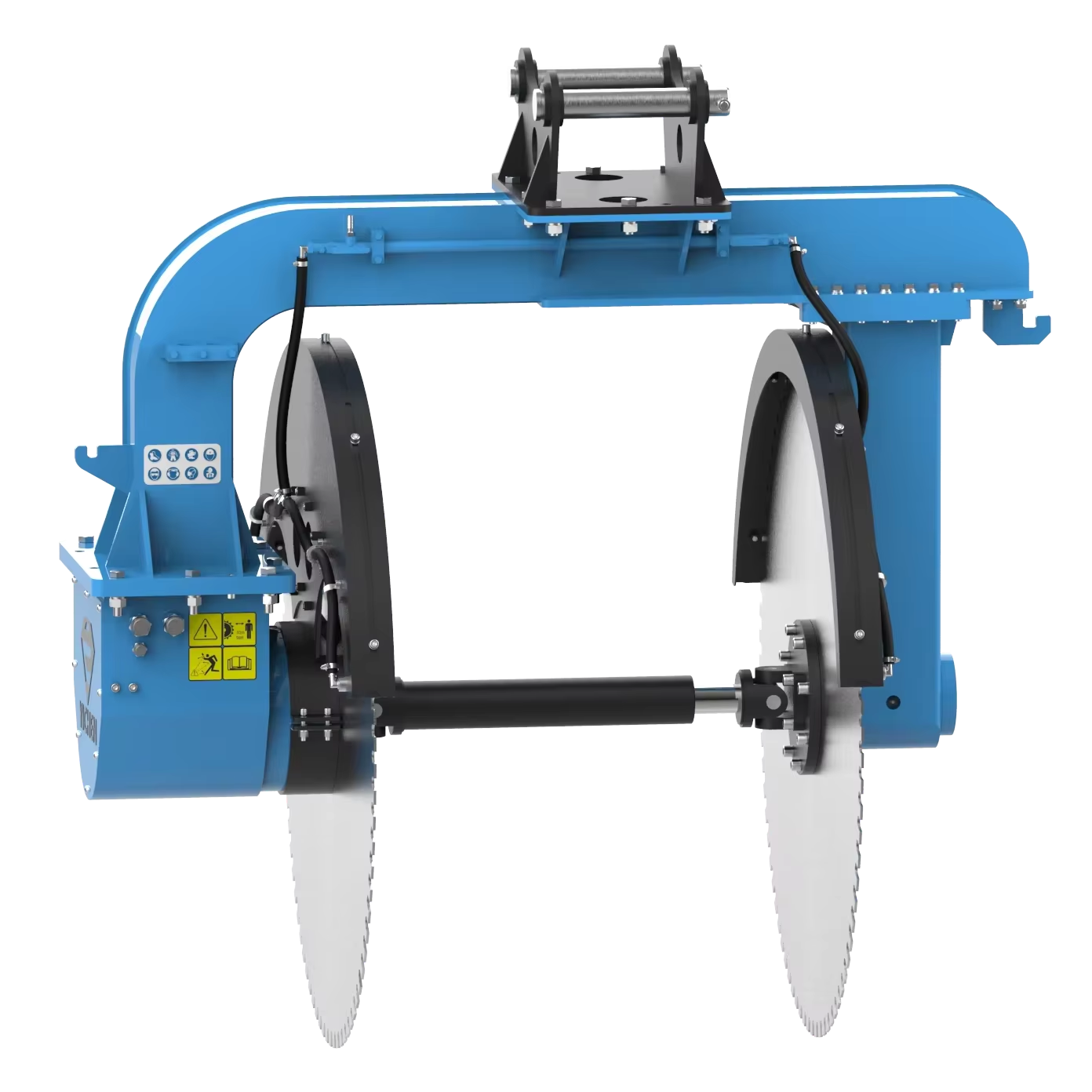

Excavator-Mounted Rock Saws: Enhancing Mobility Across Rugged Terrains

Excavator-mounted rock saws are increasingly used on challenging job sites where traditional equipment struggles with uneven terrain. These systems retain full excavator mobility while adding precision cutting capabilities−particularly advantageous in quarries and mountainous areas with slopes under 22° (Geotechnical Equipment Review 2024).

Adaptability to Various Rock Types and Site Conditions

Modern rock saws effectively cut granite (Mohs 6−7), basalt (Mohs 5−6), and reinforced concrete with consistent performance. Advanced hydraulics automatically adjust blade speed (120−250 RPM) and downward force (8,000−15,000 psi) based on material density, minimizing manual recalibration between strata.

Seamless Integration With Existing Excavator Fleets for Rapid Deployment

A 2024 study found contractors reduced setup time by 65% when attaching rock saws to existing 20−30 ton excavators versus deploying standalone units. Standardized mounting brackets and hydraulic quick-connect systems allow crews to switch between buckets, breakers, and saws in under 15 minutes−key for operations requiring frequent tool changes.

Growing Trend: Shift From Manual and Explosive Methods to Mechanized Rock Saw Systems

In 38 states across America, regulations require vibrations to stay under 2.5 mm/s near sensitive buildings, which explains why rock saws are being used in around 73 percent of city construction jobs according to data from Construction Technology Institute back in 2023. When contractors switch from traditional drilling and blasting methods to these modern cutting systems, they often finish their work about 40% quicker. Take for instance the recent highway project in Colorado where crews saved themselves a whole week's worth of time because they didn't have to wait through those lengthy permit processes required for blasting operations.

Long-Term Cost Efficiency and Labor Optimization

Labor Savings Through Reduced Crew Size and Faster Setup Times

Rock saws reduce labor requirements by 40% compared to traditional blasting crews (Construction Efficiency Report 2023). Rapid deployment allows teams to begin cutting within 30 minutes of arrival, freeing personnel for parallel tasks and improving overall site productivity.

Lower Maintenance and Downtime Compared to Blast-Based Operations

Rock saws eliminate recurring expenses tied to explosives procurement and blast-site remediation−costs that can consume 15−20% of mining budgets. Unlike blasting, which demands daily safety inspections and regulatory compliance checks, saws operate continuously with routine blade changes required only every 120−150 cutting hours.

Balancing Upfront Investment With Long-Term ROI and Operational Savings

Despite higher initial costs ($85k−$200k), rock saws deliver an average 5.3-year ROI, outperforming blasting through three key advantages:

- Labor optimization: 3-person crews replace 8−10 member blasting teams

- Downtime reduction: 92% operational uptime vs. 67% for blast/drilling cycles

- Material conservation: Precision cutting preserves 18−22% more sellable stone per project

According to the 2023 Construction Efficiency Report, combined labor, equipment, and waste savings reduced total project costs by $27−$41 per ton in granite quarrying operations.

Frequently Asked Questions (FAQ)

What are the main advantages of using rock saws over traditional methods?

Rock saws offer advantages such as faster cutting speeds, improved precision, reduced downtime, and lower environmental impact compared to traditional methods like pneumatic hammers and blasting.

How do rock saws contribute to workplace safety?

Rock saws significantly reduce vibrations and particles in the air, lowering risks for workplace injuries and minimizing potential harm to surrounding structures.

Are rock saws suitable for cutting various types of rock?

Yes, modern rock saws are adaptable and can effectively cut granite, basalt, and reinforced concrete, thanks to their advanced hydraulics and diamond-tipped blades.

What is the typical ROI for investing in rock saw systems?

Rock saws typically deliver a 5.3-year ROI through labor optimization, reduced downtime, and enhanced material conservation, making them a cost-effective investment.

Table of Contents

-

Superior Efficiency and Productivity in Hard Rock Saws Applications

- High-Speed Cutting Performance in Dense Rock Environments

- Daily Output Gains: Cubic Meters Processed With Rock Saws vs. Traditional Methods

- Comparison of Mechanical Rock Saws and Blasting: Speed, Consistency, and Operational Flow

- Case Analysis: Blasting vs. Rock Saws in Safety, Environmental Impact, and Project Timelines

- Unmatched Precision and Clean Cuts for High-Value Applications

- Mobility, Versatility, and Integration with Existing Equipment

- Long-Term Cost Efficiency and Labor Optimization

- Frequently Asked Questions (FAQ)